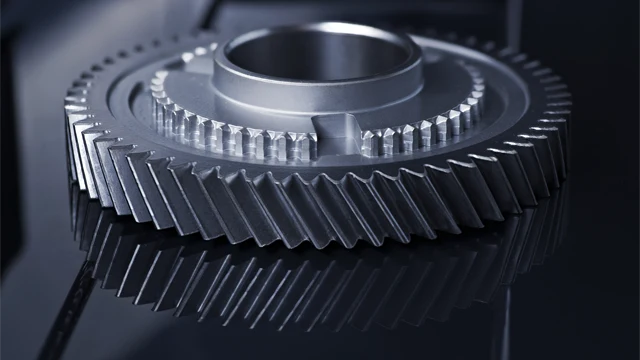

Crank- and camshaft sprockets require precise tooth profiles, high core strength and exceptional wear characteristics to allow for maintenance-free, non-slip operation.

Using powder metallurgy (PM) for manufacturing of sprockets allows for near net-shape complex geometries with reduced need for machining.

Höganäs offers material solutions that perfectly balance precision geometry with high strength and wear requirements. Ensuring better dimensional consistency and density distribution, they also feature machining enhancers that greatly reduce tool wear.

|

Benefits of Höganäs’ solution for PM crankshaft sprockets:

|

||

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.